Okara: Including a soya by-product into the poultry diet

Problem

The inclusion of soya meal into the poultry diet is relevant, as a source of high quality protein. However, as soya is planted for both human and animal consumption, the cost is high.

Solution

The production of tofu and soymilk generates okara as a waste product which can be added fresh or dried, to poultry rations, reducing both soya meal inclusion and costs. Due to its high fibre content, the amount of okara in the diet should be limited to avoid a decrease in feed intake.

Benefits

The inclusion of okara in the poultry diet has several advantages. The main advantage is related to sustainability, due to the fact that a by-product is used and not wasted. The second advantage is a reduced dependency on soya meal as a source of protein and amino acids. Finally the decrease in soya meal results in a lower cost of feed.

Applicability box

Geographical coverage

Global

Application time

Related to the tofu and soymilk production

Required time

A few days related to the supply

Period of impact

All the year

Equipment

Storage, mixer

Best in

Ration planning, reducing soya meal and feed cost

Practical Recommendations

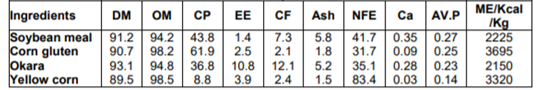

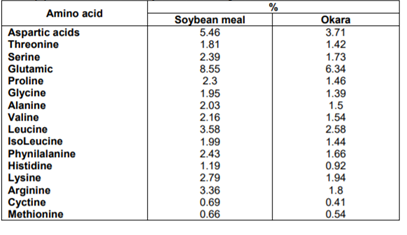

- Due to its chemical and amino acid composition (Table 1 and 2), Okara can be used in different ways in the poultry diet. A possible use is to include okara in the starting and growing phases (from the 1st to 21st day). Another possibility is to feed okara from week 1 to slaughtering time. Okara inclusion replacing soyameal quantity from 25 to 75 % in the diet, will not affect feed intake or mortality, and it will reduce ration cost and achieve comparable daily body weight gains, to 100 % soya diets. However, due to the high fibre content, overfeeding Okara, could decrease feed intake and performance (Motawe et al., 2012).

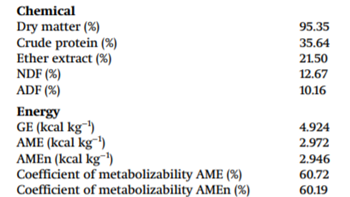

- The composition of Okara ranges between 20 % and 47.3 % protein and 9.3 % and 22.3 % fats. It contains high amounts of isoflavones and the polyunsaturated fatty acids, linolenic acid, and linoleic acid (O’Toole 1999; Bowles and Demiate 2006). The energy content is also important to ensure weight gain from day 1 to 21 (Table 3).

- According to Rostagno et al. (2011), the okara digestibility of crude protein (CP), amino acids (AA) and lipids is higher than that of soya. In particular, okara CP has a higher digestibility of around 99.6% instead of 91% . Protein content, protein efficiency coefficient, and essential AAs of okara are usually higher than those of other soybean-based products, due to the heat process that soybean undergoes during processing of the soybean aqueous extract. This makes certain AAs better available, which in turn increases the digestibility of proteins and fats (O’Toole 1999)

- It should be noted that according to Diaz-Vargas (2016), okara CP content was 21 % lower than that of soy (45%). However, the biggest difference between okara and soybean meal was in regard to tryptophan, with 55.5 % less found in okara. The contents of lysine, methionine, and threonine varied by 7.5 %, 13.3 %, and 16.5 %, respectively (Table 3).

- The economic viability of including okara in the diets was determined according to the equation described by Bellaver et al. (1985), which calculates the average cost of feed per kilogram of body weight.

Further information

Reading

- Bellaver, C., Fialho, E.T., Frotas, J.F., and Gomes, P.C. 1985. Radícula de malte na alimentação de suínos em crescimento e terminação. Pesqui Agropecu Bras. 20: 969–974.

- Bowles, S., and Demiate, I.M. 2006. Caracterização físicoquímica de okara e aplicação em pães do tipo francês. Ciênc. Tecnol. Aliment. 26: 652–659. doi:10.1590/ S0101-20612006000300026. PMID:27290722.

- Motawe, H. F. A.P 1 P ; A. M. El ShinnawyP 1 P; T. M. El-AfifiP 1 P; N.A. HashemP 1 Pand Abeer A. M. Abu ZaidP 2. UTILIZATION OF OKARA MEAL AS A SOURCE OF PLANT PROTEIN IN BROILER DIETS. (J.Animal and Poultry Prod., Mansoura Univ., Vol.3 (3): 127 - 136,2012).

- M. Diaz-Vargas, A.E. Murakami, I.C. Ospina-Rojas, L.H. Zanetti, M.M. Puzotti, and A.F.Q.G. Guerra. Use of okara (aqueous extract residue) in the diet of starter broilers (Canadian Journal of Animal Science, 2016, 96(3): 416-424, https://doi.org/10.1139/cjas-2015-0064).

- O’Toole, D.K. 1999. Characteristics and use of okara, the soybean residue from soy milk production—a review. J. Agr. Food Chem. 47: 363–371. doi:10.1021/jf980754l.

- Rostagno, H.S., Albino, L.F.T., Donzele, J.L., Gomes, P.C., Oliveira, R.F., Lopes, D.C., Ferreira, A.S., and Barreto, S.L.T. 2011. Tabelas brasileiras para aves e suínos: composição de alimentos e exigências nutricionais. 3nd ed. Universidade Federal de Viçosa, Viçosa, MG, Brazil. 119 pp.

- Check the Organic Farm Knowledge platform for more practical recommendations on animal husbandry.

About this practice abstract and OK-Net EcoFeed

Publishers:Associazione Italiana Agricoltura Biologica (AIAB),

IT89035Bova Marina (RC),

Phone +39 0965 764992,

,

aiab.itResearch Institute of Organic Agriculture (FiBL),

CH5070Frick,

Phone +41 62 865 72 72,

info.suisse@fibl.org,

www.fibl.orgIFOAM Organics Europe,

BE1000Brussels,

Phone +32 2 280 12 23,

www.organicseurope.bio,

www.organicseurope.bio

Review: Lindsay Whistance, Organic Research Centre, UK

Contact: eugeniopapi1@gmail.com

Permalink: https://organic-farmknowledge.org/tool/37898

https://orgprints.org/view/projects/OKNetEcoFeed.html

This practice abstract was elaborated in the Organic Knowledge Network on Monogastric Animal Feed project. The project is running from January 2018 to December 2020. The overall aim of OKNet EcoFeed is to help farmers, breeders and the organic feed processing industry in achieving the goal of 100% use of organic and regional feed for monogastrics.

Project website: https://ok-net-ecofeed.eu/

IFOAM Organics Europe (project coordinator), BE; Aarhus University (ICROFS), DK; Organic Research Centre (ORC), UK; Institut Technique de l'Agriculture Biologique (ITAB), FR; Research Institute of Organic Agriculture (FiBL), CH; Bioland, DE; Associazione Italiana perl'Agricoltura Biologica (AIAB), IT; Donau Soja DS, AT; Swedish University of Agricultural Sciences, SE; ECOVALIA, ES; Soil Association, UK.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 773911. This communication only reflects the author’s view. The Research Executive Agency is not responsible for any use that may be made of the information provided. The authors and editors do not assume responsibility or liability for any possible factual inaccuracies or damage resulting from the application of the recommendations in this practice abstract