Guide for assessing the protein quality in soya feed products

Problem

Soya beans are an excellent source of protein but they also contain anti-nutritive components, which need to be deactivated by heat prior to feeding to swine or poultry. However, high temperatures can also damage key nutrients, reducing their digestibility.

Solution

Trypsin inhibitor activity (TIA), protein dispersibility index (PDI) and urease activity are useful indicators in soya products to assess the quality of soya bean processing and help to predict availability and digestibility of nutri-ents. Most feed laboratories can measure these parameters. In addition, specialised near infra-red spectrosco-py (NIRS) can now measure the availability of amino acids.

Benefits

Regular monitoring of key soya bean processing indicators is essential for achieving a consistently high product quality. Results can be also used by animal keepers for planning feed rations.

Applicability box

Geographical coverage

For all farms where soya can be grown

Application time

On demand

Equipment

Sample bags and standard lab equipment

Best in

Farms with animal husbandry and arable production

Practical Recommendations

Processing intensity is key to quality

Common procedures for the heat treatment of soya beans are toasting, steaming and extrusion. The purpose of these procedures is to deactivate anti-nutritive components such as trypsin inhibitors. However, applying high temperatures inevitably leads to nutrient damage so the goal is to balance processing intensity. For toasted soya beans, the intensity is a function of processing time and temperature.

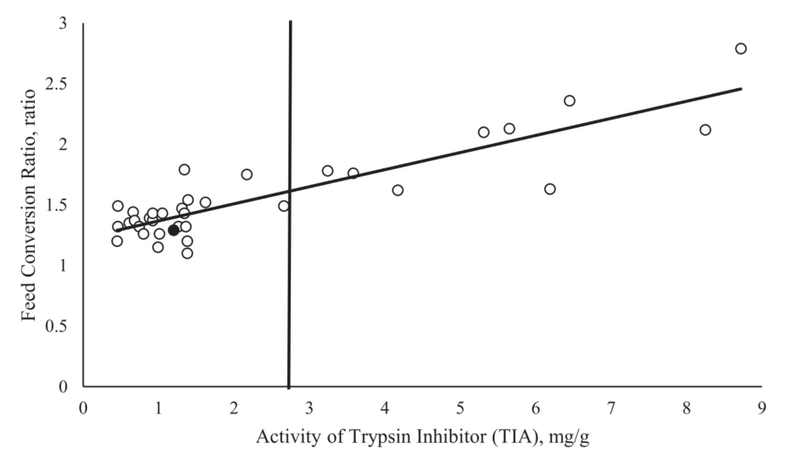

Crude protein content is a standard feed parameter, but it does not provide information on the digestibility. Processing indicators are measurable components of soya feed products which make the quality of soya bean processing (heat treatment) quantifiable. Table 1 summarises processing indicators which best predict the digestibility of the feed. Nutrient availability can be high if the values for trypsin-inhibitor activity (TIA) and protein dispersibility index (PDI) are within the target range (see numbers in Table 1). On the other hand, a poor feed conversion ratio becomes more likely if, for example, the TIA value in soya cake is higher than 4 mg/g (see Figure 1).

Table 1: Overview of processing indicators in soya bean-based feed products. Values are based on dry matter (88%). Sources: various, see in further information.

| Application | Soybeans unprocessed | Soybean feed products |

Trypsin-inhibitor activity, TIA | Trypsin-inhibitors are anti-nutritive substances which are naturally present in soya beans. TIA is reduced by heat. High TIA values in soya products can indicate poor digestibility and too low processing intensity. | Common: 30-50 mg/g DM | Recommended target range: <3 mg/g DM |

Urease activity | Urease is an enzyme naturally present in soya beans. It has little relevance for animal growth. Urease activity serves as a marker for TIA since it is also reduced by heat. High urease activity in soya products is often linked to a high TIA. Recent experiences indicate that very low values for urease activity are not suitable to assess accurately the digestibility of soya feed. If available, TIA or PDI should be used. | Common: >2 mg/g DM | Recommended target range: <0.4 mg/g DM

Note: Better to also measure TIA or PDI. |

Protein Dispersibility Index, PDI

| Protein dispersibility is based on the solubility of soya bean protein in a solvent. Most common solvents are water (PDI) or potash (PDI-KOH). PDI decreases with heat. Low PDI values in soya products can indicate damage to nutrients and a too high processing intensity. High PDI values can indicate poor digestibility due to too low processing intensity. | Common: Water: >50 % KOH: 100 % | Recommended target range: Water: 10-25 % KOH: 78-85 % |

Availability of amino acids

Reactive lysine / lysine [%] | Amino acids are the components of protein. Measuring the quality of amino acids is the best indicator for detecting damages through processing. Reactive lysine is a very suitable parameter but measurements through wet chemistry are expensive. The latest NIRS applications are low-cost and provide instant results. Reactive lysine is the part of total lysine which is digestible. It is reduced by heat. | Common: >91 % | Recommended target range: 89-90 % |

Monitoring and testing of processing indicators

The monitoring of processing indicators provides key information for ensuring the quality of soya feed products over the whole year. All common kinds of soya feed products (toasted soya beans, expeller, or solvent-meal) can be tested on urease activity, TIA and PDI. Most laboratories with a specialisation on feed analysis can measure urease activity and PDI. Analysis of TIA or amino acids are less commonly offered by laboratories in Central Europe (see also in “Further information”).

Even under routine operating conditions it is fundamental to collect a correct, representative sample so that any subsequent analytical work and interpretation makes sense. The monitoring of the processing indicators of soya products can be compared with the guidelines applied in other crop quality management and assurance schemes.

The following list contains guidance points which are special for soya bean processing indicators:

- When soya bean processing equipment is operating for the first time, frequent testing is necessary until a constant product quality can be reached.

- More frequent testing is recommended if the processing equipment is not continuously in use or if the processing settings are frequently changed.

- Experienced operators of soya bean processing equipment can detect changes in processing performance by the taste of the soya product. However, tasting provides only a rough indication and cannot replace lab tests.

- An adequate sample weight is usually 0.5 kilogram.

- Occasional testing of unprocessed soya beans is advisable since the quality can differ significantly between each batch.

- It is essential that soya beans are standardised for particle size, purity, and moisture content prior to processing. Ideal conditions can also differ depending on the processing equipment used.

Further information

Reading

- Van Eys, J.E. 2015. Manual of Quality Analysis for Soybean Products in the Feed Industry. 2nd Edition. Published by U.S. Soybean Export Council. Available under: www.ussec.org

- Organic Farm Knowledge provides access to further literature on soybean processing.

- AGES - Austrian Agency for Health and Food Safety. AGES offers an evaluation of feed tests and is capable of analysing also trypsin inhibitor activity. Further information on the AGES website: www.ages.at/en

About this practice abstract and OK-Net EcoFeed

Publishers:Verein Donau Soja,

AT1010Wien,

Phone +43 1 512 17 44 10,

office@donausoja.org,

www.donausoja.orgResearch Institute of Organic Agriculture (FiBL),

CH5070Frick,

Phone +41 62 865 72 72,

info.suisse@fibl.org,

www.fibl.orgIFOAM Organics Europe,

BE1000Brussels,

Phone +32 2 280 12 23,

www.organicseurope.bio,

www.organicseurope.bio

Contact: rittler@donausoja.org

Permalink: https://organic-farmknowledge.org/tool/35520

https://orgprints.org/view/projects/OKNetEcoFeed.html

This practice abstract was elaborated in the Organic Knowledge Network on Monogastric Animal Feed project. The project is running from January 2018 to December 2020. The overall aim of OKNet EcoFeed is to help farmers, breeders and the organic feed processing industry in achieving the goal of 100% use of organic and regional feed for monogastrics.

Project website: https://ok-net-ecofeed.eu/

IFOAM Organics Europe (project coordinator), BE; Aarhus University (ICROFS), DK; Organic Research Centre (ORC), UK; Institut Technique de l'Agriculture Biologique (ITAB), FR; Research Institute of Organic Agriculture (FiBL), CH; Bioland, DE; Associazione Italiana perl'Agricoltura Biologica (AIAB), IT; Donau Soja DS, AT; Swedish University of Agricultural Sciences, SE; ECOVALIA, ES; Soil Association, UK.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 773911. This communication only reflects the author’s view. The Research Executive Agency is not responsible for any use that may be made of the information provided. The authors and editors do not assume responsibility or liability for any possible factual inaccuracies or damage resulting from the application of the recommendations in this practice abstract